My introduction to fiber optics was in 1978 at Bell Labs in Murray Hill, being introduced to the people there who were developing the technology. AT&T wanted the company I worked for, Data Precision, to build fiber optic test equipment for them. Since D-P was not interested, I took the idea, worked on a plan for over a year, then convinced my wife Karen and created Fotec.

At Bell Labs, I remember particularly the office of Jack Cook who later left and founded Dorran Photonics making Biconics and sold it to 3M. Jack's office was funny - a tiny typical Bell Labs office but his had a plastic molding machine in the corner and dozens of biconic pigtails hanging over the door like the entrance to a New Jersey Italian restaurant! Jack and Dorran later became great customers of Fotec, using our equipment in their manufacturing of connectors. Others we met would lead to one of our biggest early projects, making manufacturing stations for AT&T's lasers.

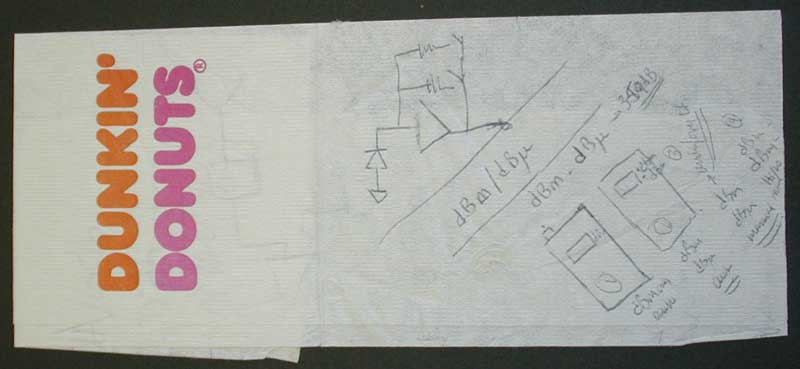

You know the jokes about starting a company on a napkin? Fotec literally started with a circuit diagram on a Dunkin Donuts napkin! The first products were nothing but an op amp and a special transistor that created a circuit that measured in dB, a trick I learned from my car pool mate at Analog Devices, Dan Sheingold, a circuit genius.

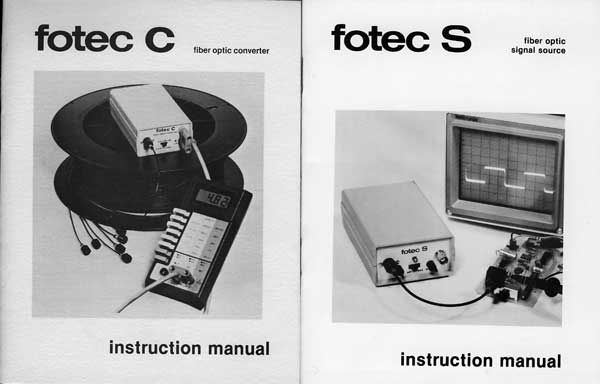

Fotec began shipping its first products in September 1981, devices that converted digital voltmeters into fiber optic converters, an interim product until our first fiber optic power meters and sources shipped the next year. We thought we might be the first fiber optic test equipment company, but Photodyne and maybe a couple of Japanese companies beat us by a few months.

Instruction manuals for first Fotec products in 1981

By early 1982, the company expanded the product line to include test sources and a handheld power meter. Combining meters and sources into “test kits” created a complete test solution that became popular with large numbers of customers, especially the computer companies such as DEC and Wang who were just introducing their first fiber optic products.

Soon after sales begun, it became apparent that most customers were not adequately knowledgeable of fiber optic technology. To alleviate this problem, Fotec had developed a training program for DEC which was then used to train their instructors who trained DEC personnel. We adapted that program to a portable seminar and training became an integral part of the company’s marketing strategy. As we gave the program around the world, we invited other companies to join us, like 3M, OFTI, Northern Lights Cable, Automatic Connector, etc. developing great business relationships. By training people in this new technology, Fotec developed a group of loyal customers for its test equipment. In the case of many of the volume customers like DEC, Fotec provided the curriculum and trained their trainers to give the program to their engineering and service personnel. From 1982 until 1992 when Fotec started the Fiber U programs, Fotec trained an estimated 7,000 people in these introductory courses.

In this new industry, standards were nonexistent. Component specifications, testing procedures and even primary measurement standards necessary for the orderly expansion of the market were missing. As a representative of Fotec, I participated in the EIA fiber optic standards committees, military standards groups, IEE and ANSI (FDDI) committees and was personally responsible for the NIST (then NBS) program for calibration of fiber optic power, the primary standard for all fiber measurements.

In 1983, I goaded NBS (now NIST) into developing a fiber optic power standard, showing them how one govt project we were involved in was jeopardized by two fiber optic power meters that measured power almost 3 dB apart. I made many trips to Boulder working on that project, providing them with detectors and products as well as helping design the program. Around the same time, I joined the EIA fiber committees and I wrote or co-wrote many of the early fiber optic standards for measurements.

Fotec participated in some neat projects.

We built the manufacturing equipment for AT&T's long wavelength lasers, IBM's first fiber product and H-P POF assemblies. We sold custom automated multichannel testers (up to 200 channels) for the R&D labs of Hughes, GTE, Polaroid, and many others. We built a custom fiber optic microphone for an EMP test site and built OEM test equipment for many other companies around the world.

People always wondered about us because they could not figure out where we were getting our business since we did not sell to telcos - but the OEM, system and data markets were good to us! We also never made an OTDR - we had a joke about that - "What do you call a fiber optic test equipment company that doesn't make an OTDR?" PROFITABLE!

Fotec built custom manufacturing stations for AT&T's first long wavelength (1310 nm) lasers for singlemode fiber. As part of the deal, we became the first customer to get these lasers and built them into test equipment for the early singlemode fiber projects. These early lasers were notoriously expensive and unreliable - we paid AT&T $3500 each for early units and a very large number never survived burn-in. Our deal with AT&T was we had to return them in exchange for new ones so they could analyze the failures to improve production. Today these same lasers can be bought for under $10!

In the mid-1980s while visiting the fiber optic labs at Hughes while we were working on a large multichannel environmental test system, I noticed they used a large HeNe laser to view the light in a fiber. I concluded that would be a great troubleshooting tool for field use, but the size of the laser was a problem, as was the 2500 volt power supply it needed. After some digging, I found a laser and power supply small enough to fit in a briefcase size case along with a motorcycle battery to make it portable and the Fotec S600 "visual fault locator" was invented. One of the first field demos was for MCI in a hut in rural Georgia where we found a broken fiber that they could not find otherwise, so they starting equipping every tech with one. It was several years later before CD lasers at visible wavelengths became available to make the VFL small.

Fotec S600 and current VFL

An interesting aside to the S600 story is how we attached singlemode fiber to the HeNe laser. We began using GRIN lenses, a 2mm graded -ndex lens coupled to a fiber. At about the same time, Fotec was working with Eastman Kodak on a top secret connector project. They were using their expertise in molding lenses to create an expanded beam connector for singlemode fiber to ease the alignment problems. Fotec was supplying test equipment and designing and building a field termination kit that did active alignment of the lenses to the fiber. When the ceramic ferrule connector was announced, they cancelled the project (writing off ~$15million). They had thousands of these expanded beam connectors made into patchcords, so Fotec bought them for practically nothing and used them in S600s- they were better than the GRIN lenses for coupling the HeNe laser into singlemode fiber.

Fotec was asked by a military customer if there was some way to talk over the fiber for security. The resulting product, FOtalk, was the first fiber optic talkset and became a popular project for field techs to communicate over the fiber they were installing and testing.

Tech using a FOtalk talkset during a LAN installation

Fotec became involved in building sensors also. We built a fiber optic sensor for IBM to measure the flatness of 8" wafers for ICs, a fiber optic weight sensor that was tested to weigh trucks at toll booths and that could be used for intrusion alarms (proposed for monitoring nuclear facilities as part of the START treaty) and a fiber optic headset for use in a military EMP test facility.

We worked on a fiber tap project for one company that led to our presenting a paper at a military conference in DC on how to tap fiber, detect tapping and prevent data loss. The paper was classified and I got to present it to a one-way mirror with armed guards on each side of me! I still get contacted about that paper after10 it was unclassified 20 years later.

Along with Felix Kaptron at ITT, we analyzed data from splicing tests and determined the cause of OTDR "gainers," the mismatch in fiber MFD or core diameter.

We participated in the process that made 62.5/125 fiber the standard - caused by IBM with their project for the 3044 Channel Extender. AT&T provided the transceivers but they were specified to work on 62.5/125 fiber. ITT/EOPD was making the fiber for AT&T who was trying to keep up with SM demand. Everybody saw IBM standardizing on 62.5/125 fiber so they said "we can too"

During the 80s, we found out that besides needing test equipment, our customers needed training. We teamed up with other companies to do seminars and estimate that we got 10,000 people started that way. Our big training assignments were for the minicomputer companies, DEC, WANG, PRIME, etc. where we sold them test equipment and gave them training curriculum and trained their trainers. Perhaps the most influential Fotec project was "Fiber U" our big training conferences. We ran Fiber U's for our own customers, trade shows and many organizations. Today, I still have people who tell me they got started in fiber at Fiber U and remember Lennie Lightwave!

Photos from some of the Fiber U conferences. We had over 200 attendees at many but with ~40 vendors, we could have small hands-on sessions.

In the middle of the 1990s we found that our customers wanted tools as well as test equipment. We had been buying and using tools in our training, so we began offering tool kits with a full set of installer tools and a set of test equipment. By the end of the 1990s, more than 1/3 of all our orders included tools. We sold so many tools we were able to get special tools created for fiber techs.

Fotec tool kit for fiber techs

Fiber U also led to the Fiber Optic Association which we run today - managing hundreds affiliated schools and has certified over 86,000 fiber optics technicians! (as of 2021)

The Fotec and Fiber U websites went online in 1994 - some of the first commercial websites - and offered online training in 1997 - again one of the first! By the time we sold Fotec, we had 20,000 people per month taking online training sessions. The first Fotec website was used an online applications guide as well as product catalog. That website included hundreds of pages of technical and product information. A online storefront was set up in late 1998, that sold Fotec products, Fiber U training and distributed components like fiber optic connectors. Fiber U Online began in 1997/8 and offered free online learning programs in fiber optics and (by popular demand) premises cabling (copper/fiber/wireless).

Fotec had a great run - 20 years until Fluke bought us just before the 2001 fiber optic market crash! As Fluke was closing Fotec in 2002, our third customer from 1981 contacted us in a panic to get his Fotec unit recalibrated before we closed.

A mesure of the success of Fotec is the number of Fotec instruments and kits that show up on eBay today. We've purchased about 2 dozen of them ourselves - every one worked perfectly and meters were still in calibration after 20 years - and donated them to training programs.

Fotec Time Line

8/80 Jim Hayes begins planning for a fiber optic test equipment company

3/81 Fotec business plan written, circulated to private investors

9/81 Fotec sells first product, the Fotec C, adapters for converting electrical instruments like DMMs to FO power meters

82 First fiber optic "test kits" (meter, source and accessories)

83 Massachusetts Technology Development Company (MTDC, the state VC agency) invests in Fotec

83 First training sessions for DEC and Wang

6/83 First FO component tester

9/83 Begins publishing FO Testing Newsletter

11/83 Begins working with NBS to develop traceable power standards

5/84 Begin nationwide seminars on basics of FO

6/84 First test sets for SM fiber using first AT&T 1310 lasers

12/84 Training videos and Pocket Test Guide

1/85 First multichannel FO testers for component evaluation'

3/85 Fotec chosen to design first military FO field test equipment for SUBACS

11/86 Field portable HeNe Laser (S600, above)

6/87 FO talk - First fiber optic talkset

6/88 GSA Contract for FO test equipment

9/88 Research creates universal launch cable (ULC) for testing

3/89 Fiber optic microphone and intrusion sensor projects

12/89 Mini Series instruments and FOtracer

6/90 Installers network started

12/90 Fotec honchos Interop FDDI fiber install

1/91 Patent on universal launch cable (ULC) and source

6/91 First meters for CATV high power levels

1/92 LCT100 - FDDI protocol tester - developed with customer

3/93 F310 "smart meters" integrate with PCs and store data

7/93 First Fiber U conference in Nashville

9/93 FOtest software for smart meters integrates PC with instruments

3/94 Smart sources automate FO loss testing, automate wavelength identification

9/93 Fotec publishes first book on FO testing

9/93 First FO test kit under $1000

3/94 Smart meters offer dual wavelength identification and 0.001 dB in portable instruments

4/95 FOdoc software for cable plant documentation introduced

7/95 Fotec creates product and technical website

7/95 Co-founded FOA

10/95 Fiber U @ NECA begins series of Fiber Us at major conferences

4/96 Lennie Lightwave's Guide To Fiber Optics published

5/96 FOtest'r (automated tester) and FO toolbox (tools + test equipment

9/96 First Fiber U Self-study course

6/97 A490

12/97 Portable oven for curing epoxy connectors

1/98 FOtest'R cable certifiers automate testing

11/98 Fiber U online training website launched

5/00 Anaerobic adhesive technique developed, approved by Navy in 5/01

3/01 Fotec sold to Fluke Networks

4/02 Fotec Closed!